Challenge: Maximizing Efficiency

A 50 MW onshore wind farm, of 20 Nordex N90-2500 turbines operational since 2009, changed ownership. This acquisition marked a strategic move to revitalize an aging asset in a low-wind region. Given the farm's advanced age and suboptimal wind conditions, the new owner sought to enhance performance and maximize returns on investment by implementing an optimization plan.

The unique challenge lay in the wind farm's location: a low-wind area where the turbines require precise blade and yaw system adjustments to maximize energy output. Originally best-in-class for such conditions, the turbines now demanded advanced monitoring to maintain peak efficiency.

The Solution: A Comprehensive Windfit Campaign

To achieve these goals, the new owner launched a yearlong Windfit campaign in 2024, deploying cutting edge technology to detect and correct performance issues across the entire wind farm systematically, particularly rotor imbalances and yaw misalignments.

Phase 1: Detection and Resolution

During the first phase, the farm installed 10 Windfit boxes to monitor an initial batch of turbines. The results were immediate and impactful: within weeks, the system identified five rotor imbalances with pitch deviations ranging from 0.6° to 1.2° (medium to high severity) and two yaw misalignments (5° and 9°).

With the support of a skilled local maintenance team, these issues were resolved within 3 to 4 months. Subsequent Windfit monitoring confirmed the effectiveness of these adjustments. The average annual energy production (AEP) gain estimation was 1.5% across the first batch of turbines.

Real Results, Real Impact

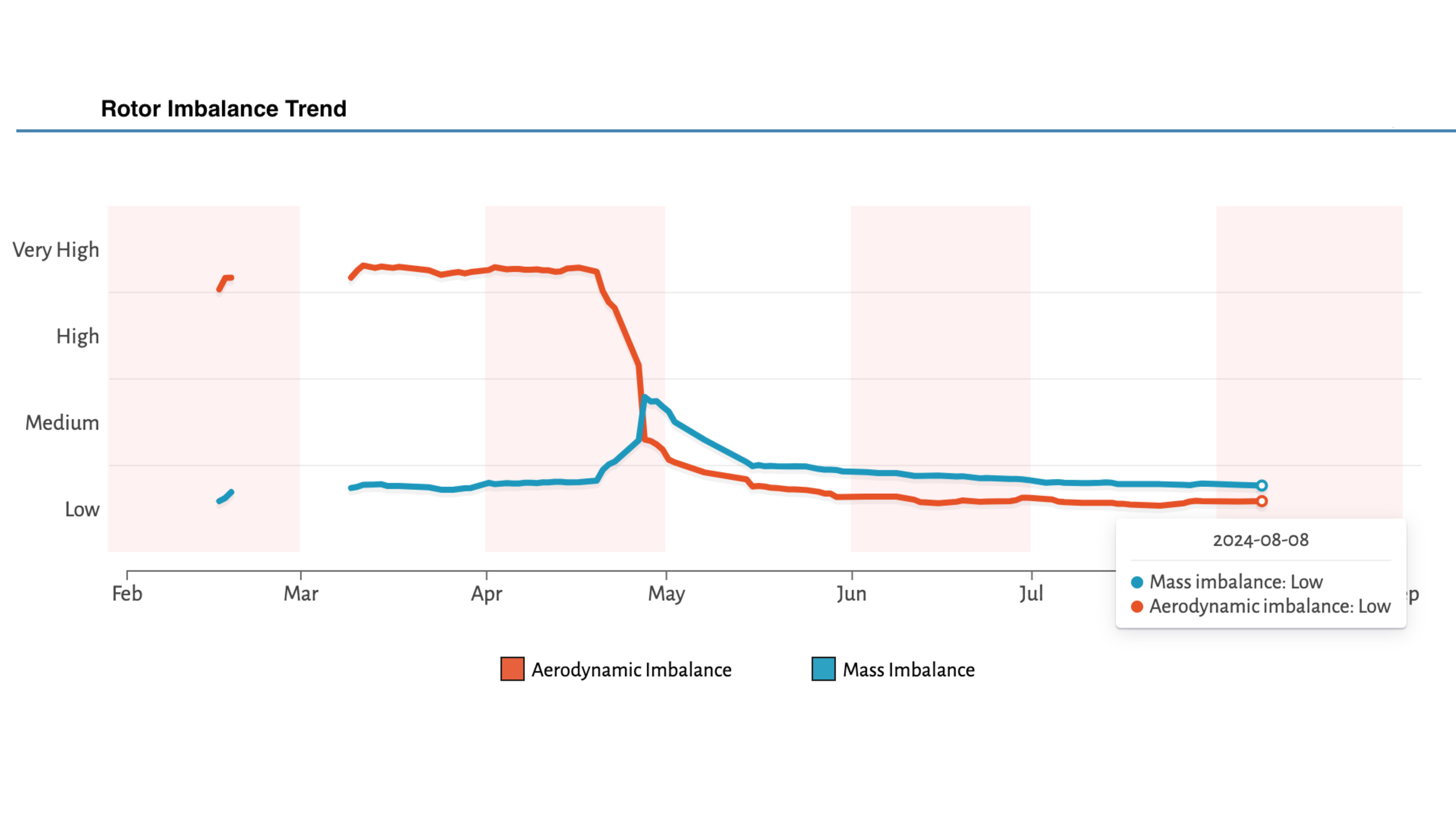

- Turbine T01:High aerodynamic imbalance detected in February 2024. Blade alignment was corrected onsite in April 2024 (-0.7° for Blades A and C). Result: A significant performance boost, with an estimated AEP gain of 1.8%.

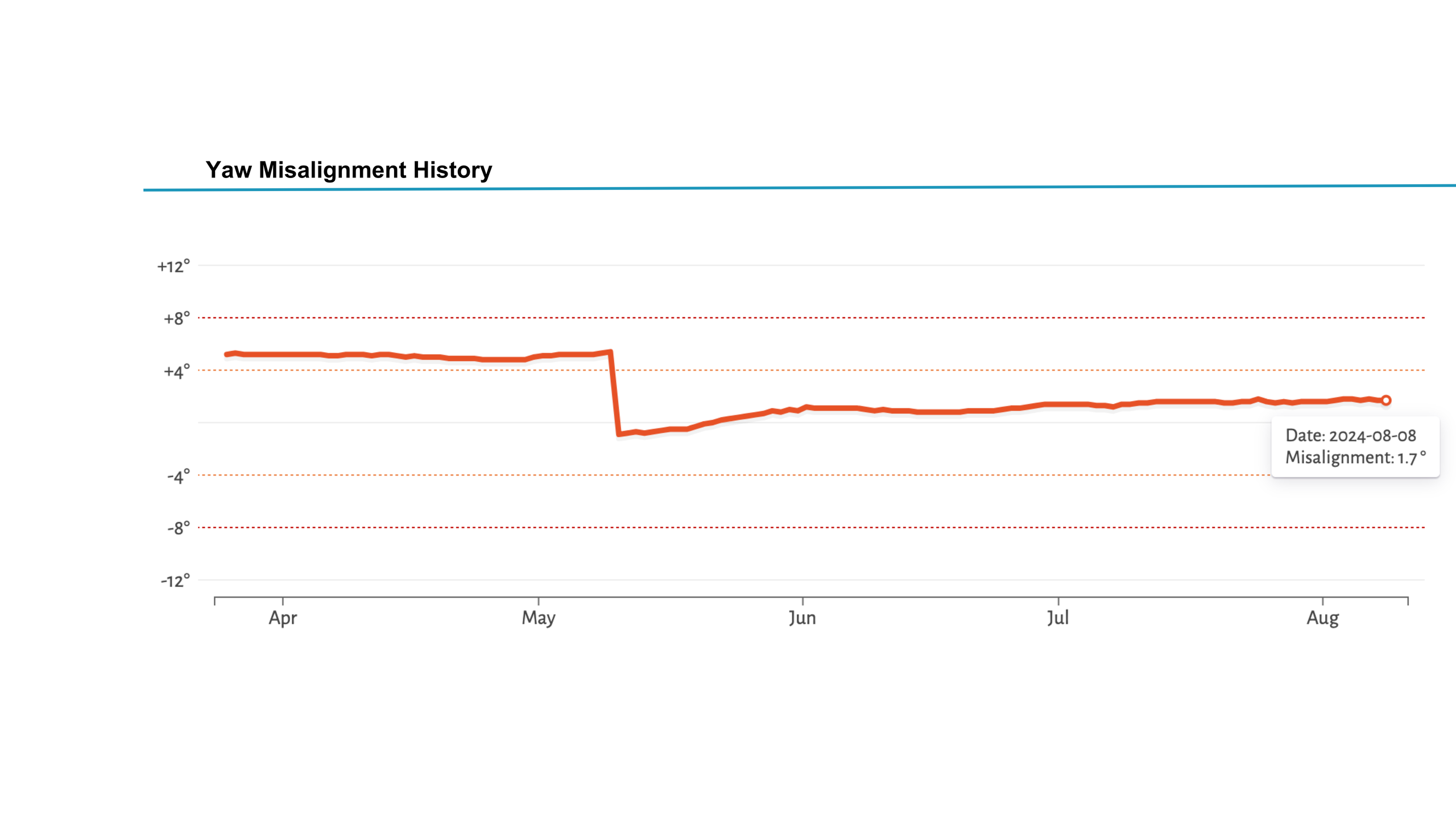

- Turbine T06: A 5.2° Yaw misalignment was detected in March 2024. A correction factor was remotely applied in May 2024, resulting in a perfect alignment of the turbine and an estimated AEP gain of 1%.

Phase 2: Expanding the Campaign’s Reach

After all the corrections were successfully applied and the results consolidated, Windfit boxes were moved to the second batch of turbines. So far, eight rotor imbalances have been detected, including two severe cases with up to 1.6° total pitch deviation. With an estimated potential AEP gain of 2%, corrective actions are planned before the end of the year.

Results: Maximised Performance and Energy Yield

The Windfit campaign's structured and data-driven approach has proven to be a game-changer for the wind farm. By precisely detecting, correcting, and validating performance issues, the Windfit campaign improved the efficiency of aging turbines and unlocked additional energy production, ensuring these assets continue to deliver optimal returns.

Conclusion: A Proven Solution for Maximising Wind Farm Efficiency

This use case showcases the transformative impact of the Windfit system on an aging wind farm. For operators facing similar challenges, Windfit stands out as a proven solution to enhance energy production, extend operational life, and maximise return on investment. It empowers wind farm owners to confidently navigate the complexities of turbine management, ensuring their assets remain high-performing for years to come.

Let's Discuss your Project!

To explore how our solutions can assist you further, we encourage you to contact us. Our team is ready to address any inquiries you may have and provide comprehensive support.

Sereema Team